Sustainability in Droppers: Eco-Friendly Materials and Designs

As the world becomes increasingly aware of the environmental challenges posed by plastic waste, industries across the globe are shifting toward more sustainable practices. The pharmaceutical and cosmetic industries, which heavily rely on droppers for dispensing liquids, are no exception. Droppers, typically made from plastic and glass, are often single-use items that contribute to plastic pollution and waste. However, with growing concerns about sustainability, there has been a shift toward more eco-friendly materials and designs in droppers to minimize their environmental impact.

This blog explores the role of sustainability in the design and manufacturing of droppers, focusing on the eco-friendly materials and innovations that are transforming this essential healthcare tool into a greener option.

1. The Environmental Impact of Traditional Droppers

Traditional droppers, made from plastic (usually polyethylene or polypropylene) and glass, have been used for decades due to their effectiveness and cost efficiency. However, as disposable items, they contribute to the growing issue of plastic pollution. Here are some key environmental concerns associated with conventional droppers:

- Plastic Waste: Single-use plastic droppers often end up in landfills or, worse, in the ocean, where they can take hundreds of years to decompose.

- Non-Recyclability: Many plastic droppers contain mixed materials (e.g., rubber bulbs and plastic parts) that are difficult to separate and recycle.

- Resource Consumption: Manufacturing traditional plastic and glass droppers requires significant natural resources, contributing to carbon emissions and environmental degradation.

As these environmental concerns have grown, there has been an increasing demand for sustainable alternatives that can serve the same purpose without the harmful effects.

2. Eco-Friendly Materials for Droppers

To address the environmental impact, many manufacturers are moving towards eco-friendly materials and design practices in the production of droppers. Here are some of the most promising sustainable materials being used:

a) Biodegradable Plastics

Biodegradable plastics are made from plant-based materials such as cornstarch, sugarcane, and potato starch. These plastics are designed to break down more easily in the environment, unlike traditional petroleum-based plastics, which can persist for hundreds of years.

- Advantages: These materials are more environmentally friendly because they degrade faster than conventional plastics. Some biodegradable plastics also have the benefit of being compostable, reducing their impact on landfills.

- Challenges: Although biodegradable, the production of these plastics still requires energy, and the decomposition process depends on specific environmental conditions. Additionally, biodegradable plastics are more expensive than traditional plastic, which may increase costs for manufacturers.

b) Recycled Materials

Using recycled plastic is an effective way to reduce the demand for virgin plastic and minimize waste. Post-consumer recycled (PCR) plastics, which are made from recycled bottles, containers, and other plastic products, can be used in the manufacturing of droppers.

- Advantages: By reusing materials, PCR plastics help conserve resources and reduce the environmental impact of producing new plastic. They also help divert waste from landfills and reduce the overall need for virgin materials.

- Challenges: The use of recycled plastic in droppers requires careful quality control to ensure that the plastic does not compromise the safety or integrity of the medication or product inside.

c) Plant-Based and Bio-Based Materials

Bio-based plastics, derived from renewable plant sources like sugarcane, corn, or coconut shells, are becoming popular alternatives to traditional petroleum-based plastics. Materials such as bio-PE (bio-based polyethylene) and bio-PET (bio-based polyethylene terephthalate) are more sustainable, as they are produced from renewable resources.

- Advantages: Plant-based plastics have a lower carbon footprint and are typically biodegradable, making them more eco-friendly. They also reduce dependence on fossil fuels.

- Challenges: While bio-based materials are better than conventional plastics, they still face scalability issues. Additionally, large-scale production can compete with food crop cultivation, which raises concerns about land use and resource allocation.

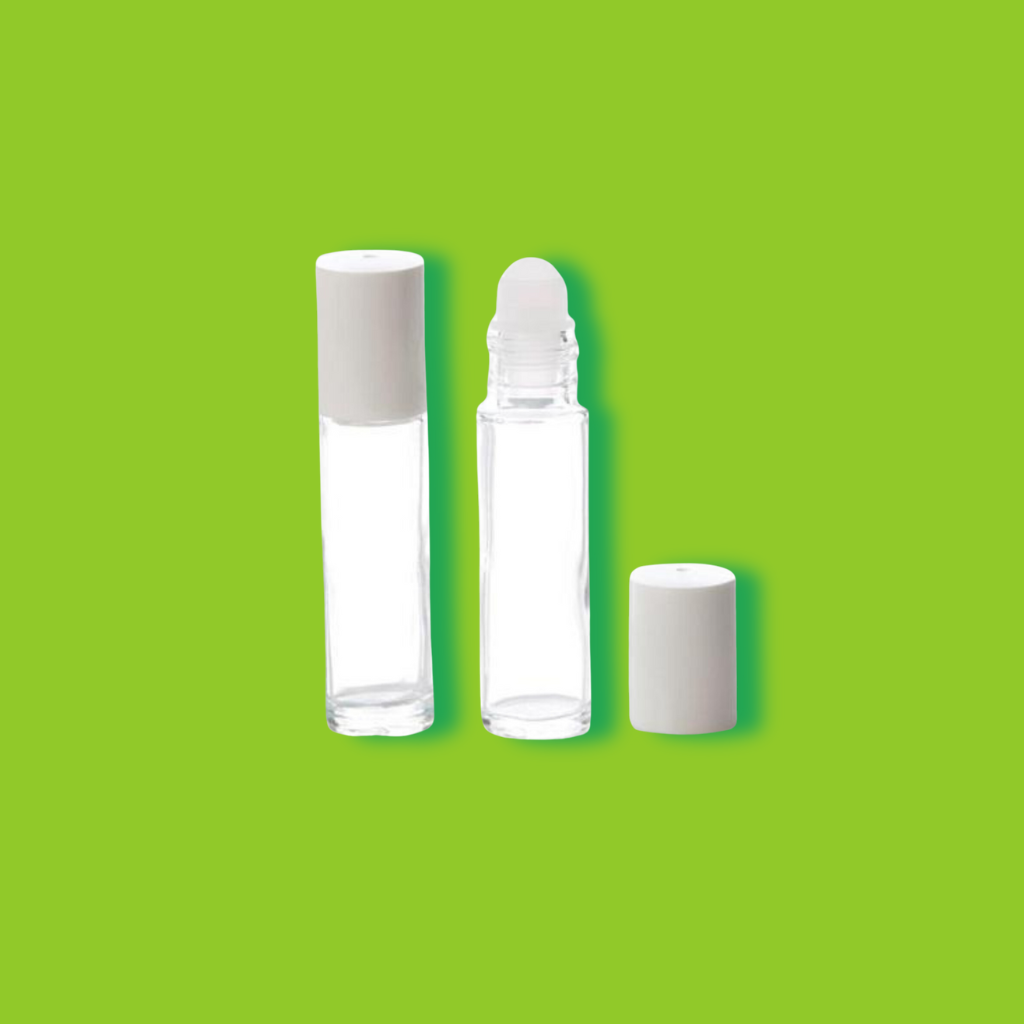

d) Glass

Glass has long been a popular material for droppers due to its non-reactivity, durability, and ability to preserve liquid formulations. Glass is fully recyclable and can be reused multiple times, making it one of the most sustainable options available.

- Advantages: Glass is infinitely recyclable, meaning it can be melted down and reformed into new glass products without losing quality. It is also highly durable and can provide a longer shelf life for medications and liquids.

- Challenges: Glass droppers are heavier than plastic, which increases transportation costs and energy use. However, advancements in lightweight glass and better shipping techniques are helping mitigate these issues.

3. Sustainable Dropper Designs

While eco-friendly materials are a critical part of the shift toward sustainability, innovative dropper designs also play a significant role in reducing environmental impact. Some of the key design improvements include:

a) Reusable Droppers

Instead of single-use droppers, there is a growing trend toward reusable droppers that can be cleaned and reused multiple times. Reusable droppers are often made from glass or durable plastics, allowing them to serve a longer lifecycle before being disposed of.

- Advantages: Reusable droppers help reduce waste by limiting the number of new droppers that need to be manufactured and discarded. They can also be more cost-effective for both consumers and manufacturers over time.

- Challenges: Reusable droppers require maintenance, such as cleaning and sterilization, to ensure hygiene. This may be less convenient for some consumers.

b) Minimalist Packaging

To reduce waste even further, many companies are adopting minimalist packaging designs for droppers. This includes using smaller bottles, less plastic, and streamlined dropper components that minimize packaging materials without compromising the functionality of the product.

- Advantages: Minimalist designs reduce the amount of material used in packaging, which lowers production costs, reduces shipping weight, and decreases the environmental impact.

- Challenges: Ensuring that the packaging is still effective at protecting the product and keeping it safe for consumers is essential. Proper sealing and tamper-evident designs are still necessary.

c) Multi-Function Packaging

Some modern packaging designs combine multiple functions in one package, such as a dropper that can double as a measuring device or a self-dosing mechanism. This reduces the need for additional components and materials, further reducing waste.

- Advantages: Multi-function packaging simplifies the product, reduces excess packaging, and offers more convenience for consumers.

- Challenges: Integrating multiple functions into a single design can be complex, and manufacturers must ensure that these designs do not negatively impact usability.

4. The Role of the Consumer in Sustainability

While manufacturers play a crucial role in improving the sustainability of droppers, consumers can also contribute by disposing of droppers correctly. Recycling programs for plastic and glass droppers are essential for minimizing their environmental impact. Consumers should:

- Follow recycling guidelines provided on packaging.

- Clean and sterilize reusable droppers after each use.

- Participate in take-back or recycling programs where available.

- Avoid using disposable droppers unless absolutely necessary.

5. The Future of Sustainable Droppers

As sustainability continues to be a top priority for industries worldwide, the future of droppers will likely see even more advancements in materials, designs, and production techniques. The key trends to watch for include:

- Bio-based materials gaining more market share.

- Closed-loop recycling systems where droppers and other pharmaceutical packaging are consistently reused and recycled.

- Smart packaging and sensors embedded into droppers that help improve functionality and reduce waste.

- Increased collaboration between manufacturers and environmental organizations to create industry-wide standards for sustainable droppers.

Conclusion

The shift toward eco-friendly materials and sustainable designs in the pharmaceutical and cosmetic industries is helping to reduce the environmental footprint of droppers and packaging. By adopting biodegradable plastics, using recycled materials, and incorporating reusable designs, the industry is making important strides toward a more sustainable future. As consumers, we can also play an active role by properly disposing of packaging and choosing products that prioritize sustainability.

As technology continues to evolve, we can expect even more innovation in the field of eco-friendly droppers, helping to preserve both our health and the planet for future generations.